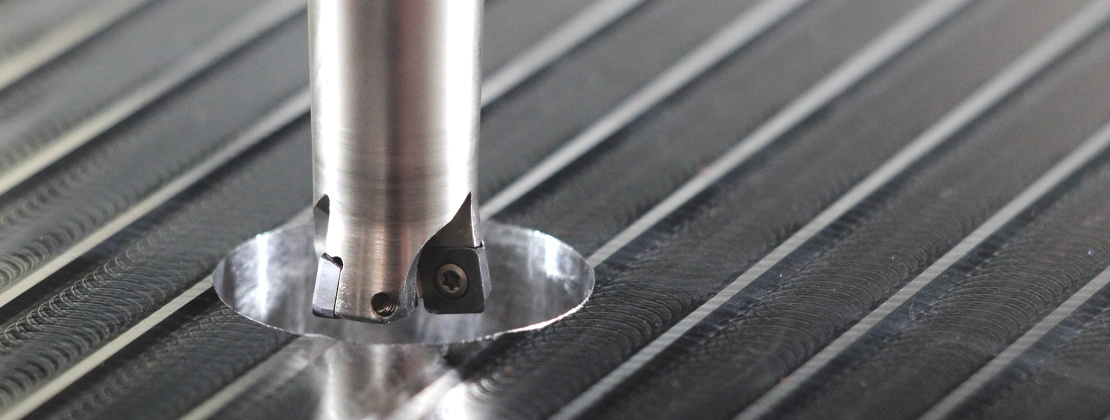

Cutting tools are tools used to remove material from a workpiece in the form of chips. They are used in a wide range of manufacturing and machining processes, such as drilling, milling, turning, and grinding. The selection of cutting tools is crucial to the efficiency and quality of the machining process. There are many different types of cutting tools available, each with their own unique characteristics and uses.

The cutting edge, which is the part of the tool that comes into contact with the workpiece, is the most important feature of a cutting tool. The cutting edge is typically made of high-speed steel, carbide, or ceramic. The choice of material depends on the type of machining being done and the properties of the workpiece. Cutting tools can also be coated with various materials to enhance their durability and performance.

When selecting a cutting tool, it is important to consider factors such as the hardness and toughness of the workpiece, the desired surface finish, and the required cutting speeds and feeds. Cutting tools can be designed with specific geometries and coatings to improve their performance in different types of machining operations.

In addition to the physical characteristics of the cutting tool, the way it is used also plays a major role in its performance and lifespan. Proper tool handling and maintenance, such as regular sharpening and cleaning, can extend the life of a cutting tool and improve its performance.

Overall, cutting tools are essential tools for any manufacturing or machining process. An understanding of the different types of cutting tools, their characteristics and uses, and proper selection and maintenance can help ensure efficient and high-quality machining operations.

In addition to the types of cutting tools mentioned above, such as drill bits, end mills, and saw blades, there are other specialized cutting tools available for specific applications. For example, reamers are used to enlarge and finish holes to precise tolerances, while taps are used to create threads on the inside of a hole. Knives and blades are used in woodworking and other cutting applications.

When it comes to cutting tools, it's also important to consider the cutting conditions, such as the speed, feed, and depth of cut. These parameters can affect the tool's performance, lifespan, and the quality of the final product.

Another important consideration when using cutting tools is the machine tool itself. The machine tool must be set up properly, aligned and adjusted, to ensure optimal performance of the cutting tool.

It's also important to consider the cutting fluids, or coolants, when using cutting tools. These fluids can help to reduce friction, heat, and wear on the cutting tool, as well as to flush away chips and debris from the cutting area.

In conclusion, cutting tools are a vital component in any manufacturing or machining process. They come in many different forms, materials, and shapes and are used to remove material from a workpiece in the form of chips. Understanding the different types of cutting tools, their characteristics, and the cutting conditions, as well as proper selection, handling, maintenance, and use, can help to ensure efficient and high-quality machining operations.

The cutting edge, which is the part of the tool that comes into contact with the workpiece, is the most important feature of a cutting tool. The cutting edge is typically made of high-speed steel, carbide, or ceramic. The choice of material depends on the type of machining being done and the properties of the workpiece. Cutting tools can also be coated with various materials to enhance their durability and performance.

When selecting a cutting tool, it is important to consider factors such as the hardness and toughness of the workpiece, the desired surface finish, and the required cutting speeds and feeds. Cutting tools can be designed with specific geometries and coatings to improve their performance in different types of machining operations.

In addition to the physical characteristics of the cutting tool, the way it is used also plays a major role in its performance and lifespan. Proper tool handling and maintenance, such as regular sharpening and cleaning, can extend the life of a cutting tool and improve its performance.

Overall, cutting tools are essential tools for any manufacturing or machining process. An understanding of the different types of cutting tools, their characteristics and uses, and proper selection and maintenance can help ensure efficient and high-quality machining operations.

In addition to the types of cutting tools mentioned above, such as drill bits, end mills, and saw blades, there are other specialized cutting tools available for specific applications. For example, reamers are used to enlarge and finish holes to precise tolerances, while taps are used to create threads on the inside of a hole. Knives and blades are used in woodworking and other cutting applications.

When it comes to cutting tools, it's also important to consider the cutting conditions, such as the speed, feed, and depth of cut. These parameters can affect the tool's performance, lifespan, and the quality of the final product.

Another important consideration when using cutting tools is the machine tool itself. The machine tool must be set up properly, aligned and adjusted, to ensure optimal performance of the cutting tool.

It's also important to consider the cutting fluids, or coolants, when using cutting tools. These fluids can help to reduce friction, heat, and wear on the cutting tool, as well as to flush away chips and debris from the cutting area.

In conclusion, cutting tools are a vital component in any manufacturing or machining process. They come in many different forms, materials, and shapes and are used to remove material from a workpiece in the form of chips. Understanding the different types of cutting tools, their characteristics, and the cutting conditions, as well as proper selection, handling, maintenance, and use, can help to ensure efficient and high-quality machining operations.