There are several factors to consider when optimizing cycle time

Machine setup

The machine setup should be optimized to maximize the effectiveness of high feed operations.

This may involve adjusting the workpiece position or orientation, ensuring proper coolant flow, or making other adjustments to optimize the cutting process

Workpiece material

The material being machined can have a significant impact on cycle times. Harder materials may require a slower feed rate or different cutting strategies to prevent tool damage or premature wear.

Cutting parameters

The cutting parameters, such as the feed rate, spindle speed, and depth of cut, must be carefully selected and optimized for the specific application.

These parameters will vary depending on the workpiece material or tool selection.

Tool selection

Choosing the right cutting tool for the job is crucial.

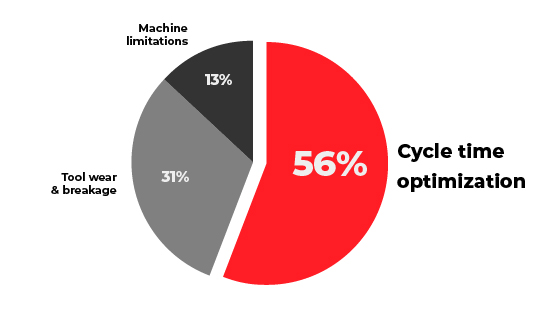

Reducing production costs in CNC machining: One of the biggest challenges

Need the perfect tool reduce your time cycle? Know more about Tetrafeed.

- Internal coolant system

- Bigger screw size to whitsland loads of demanding operations

- Robust insert with large cross section

- Improved wear resistance